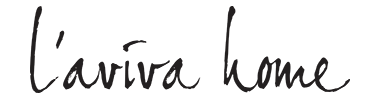

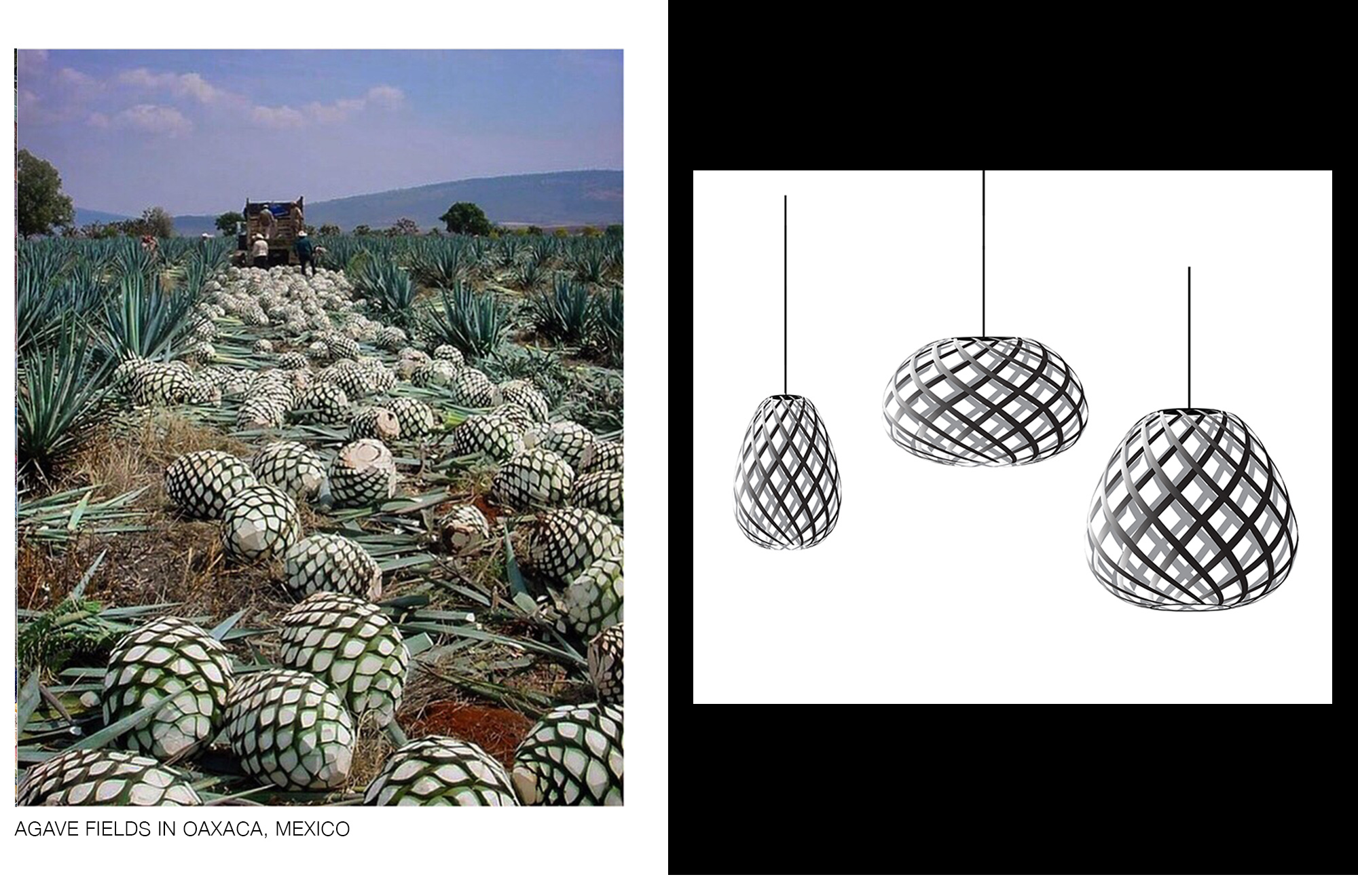

This collection is inspired by the distinctive shape and character of the piña—the heart of the agave plant—from which mezcal is made. Each lamp is individually and expertly coaxed to form in Oaxaca, where mezcal has played a vital spiritual and ritualistic role in community life for centuries. The handblown forms capture the beautiful heft of the piña, revealed in the undulating glass structures. The lamps reflect an organic symmetry that nods to both the role of nature and to that of the human hand.

Each lamp in the collection has as its namesake a different type of agave used in mezcal production: TOBALÁ, ESPADÍN and CUISHE.

Each of the various glass colors (clear, smoke and charcoal) evokes a different stage in the distillation process.

For this collection, we’ve partnered with Xaquixe, an innovative glass studio in Oaxaca, Mexico. Xaquixe pairs their expert level skill with a commitment to working with upcycled glass and alternative energies.

With studio founders Christian Thornton and Salime Harp Cruces, we began an extended dialog in which we worked together over a period of many months to develop a system to bring our designs to life.

What resulted was a multi-staged endeavor incorporating techniques and processes that were a first for all involved.

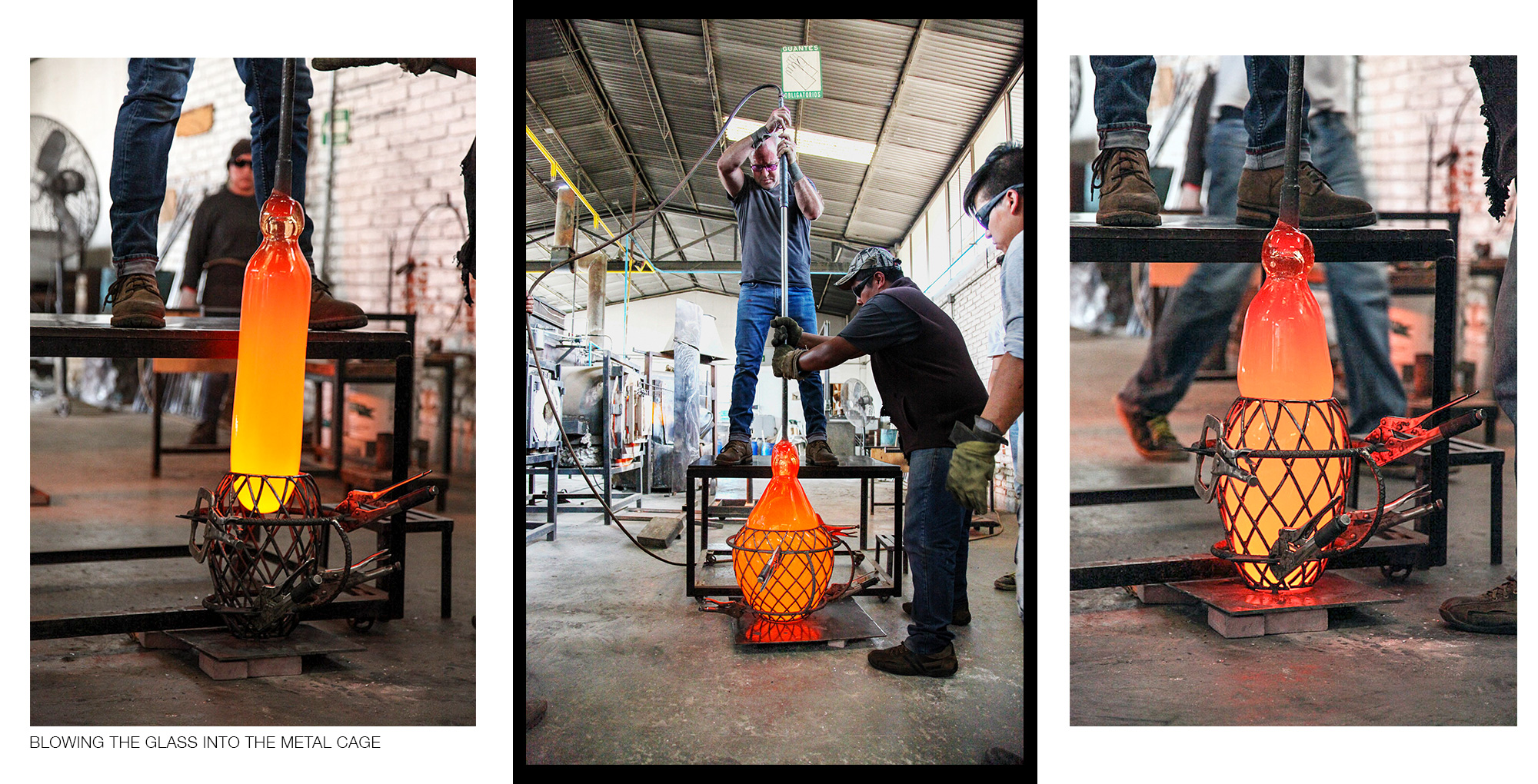

At the outset, wooden molds—carved and painted to emulate the piñas in each of the collection designs— were made to serve as a template upon which steel rods were positioned before being welded into a series of custom cages.

Once fabricated, the cages serve as the molds into which the molten glass is blown.

It’s a careful dance to get all the temperatures just right: the glass hot enough to blow into the cage with the right amount of malleability, the cage itself hot enough that it can be removed without having the glass adhere to the metal.

Upon being freed from the cage, the glass forms are finessed in a series of motions, with the team skillfully navigating the precise manipulations of each piece.

In the final stages, the lamps are carried to the annealing oven to cool, after which they are drilled, cut and polished—and left ready for electrification.

EXPLORE

OUR AGAVE COLLECTION